Grease Compatibility

The Problem with Mixing Greases

Mixing incompatible greases in your machine can have major consequences. The most likely result is a change in consistency or increased oil bleeding, especially under shear stress. This could mean that your grease is no longer the correct grade for the machine. If corrective action is not taken quickly enough, this can result in damage to the machine. In an ideal scenario you would remove all of the old grease from the machine before introducing a new one. In practice this rarely happens due to the amount of extra work it takes. Thus, choosing a new grease that is compatible with the existing one can save a lot of time and money.

Compatibility

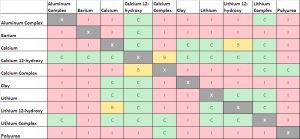

Compatibility between greases is based on three factors: thickener type, base oil, and additives. Grease compatibility charts (such as the one pictured below) can only help compare the thickener types of greases. However, these charts rarely tell the whole story, even just in terms of the thickener compatibility. You also need to consider the operating conditions of the grease (temperature, sheer rate, etc.) and the proportions in which they are mixed.

Testing

In order to fully understand whether or not two greases are compatible, you need to test them. ASTM D6185 details a procedure to check the compatibility of a binary grease mixture by mixing the two greases together in various proportions (usually 25:75, 50:50, and 75:25) and testing the resulting mixtures. You then compare these mixtures to the original in terms of dropping point, shear stability, and consistency after prolonged storage at an elevated temperature. If those properties of the mixtures compare favorably to whichever of the individual greases performs worse, they are considered compatible.

Remember, this chart may not be accurate for all greases. If you are ever unsure if two greases are compatible be sure to test them before adding a new grease to your machine.

Grease Compatibility Chart